I’m sharing some straightforward tips and techniques that have helped me prevent sublimation cracking and peeling in my projects. No drama, just practical advice to keep your work looking its best for as long as possible. So, let’s dive in and learn how I preserve the quality and integrity of my creations.

Key Takeaways

The three pillars to successful sublimation

To prevent sublimation cracking and peeling, it is important to ensure appropriate heat, pressure, and timing settings during the sublimation printing process.

What influences the three pillars?

The heat, pressure and timing settings will depend on several factors. These include the type of substrate material being used, the thickness of the material and even the presence of any pre-applied coatings.

Can I repair cracks & peels once they happen?

It varies based on the severity of the cracks or peel. Immediate cracking post-sublimation typically indicates an error in the process. It’s advisable to troubleshoot by conducting additional tests on the garment until the desired outcome is achieved. Refrain from selling compromised designs, as this can negatively impact both your reputation and business integrity.

Common Causes of Sublimation Cracking and Peeling

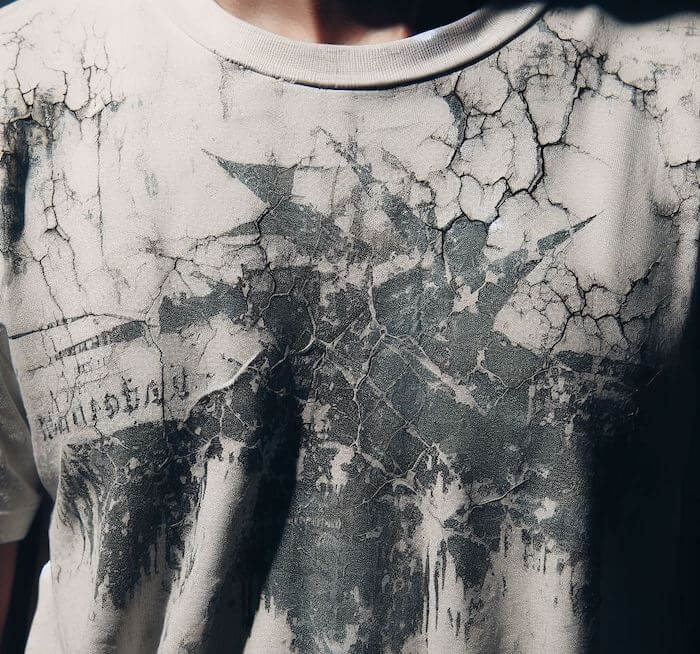

Cracking and peeling is incredibly disheartening, especially when they mar a freshly pressed print.

My first step in tackling this issue is always to identify the material I’m sublimating on. Different materials demand different settings, so I refer to a handy chart ↓ to establish my baseline settings. However, even with a chart, I’ve learned that adjustments may be necessary based on various factors, including conditions and environmental influences.

Heat Press Settings Guide for Substrates

| Substrate | Press Time / s | Temp °F | Pressure / PSI |

|---|---|---|---|

| Ceramic Mugs | 150 – 210 | 370 – 400 | 40 (medium) |

| Metals | 60 – 80 | 375 – 400 | 40 (medium) |

| Ceramic & Glass Tiles | 300 – 700 | 380 – 400 | 40 (medium) |

| Polyester Fabric | 45 | 380 – 400 | 40 (medium) |

| Sequin Pillow | 45 – 55 | 380 – 400 | 40 (medium) |

| Soft T-Shirts | 35 – 40 | 380 – 400 | 40 (medium) |

| Vapor Apparel | 45 – 55 | 380 – 390 | 40 (medium) |

| UNISUB Products | 60 | 380 – 400 | 40 (medium) |

| FR Plastics | 45 – 90 | 380 – 400 | 40 (medium) |

Peeling and cracking often occur when the optimal balance of temperature, pressure, and time is not achieved.

Did you know?

Environmental conditions such as humidity levels can also influence the efficacy of heat press machines and even sublimation printers. These can lead to premature cracking and peeling.

To ensure I nail this crucial combination, I occasionally sacrifice an actual substrate for testing purposes. This allows me to closely inspect the results and, if necessary, make adjustments to the temperature, pressure, and time until the desired outcome is achieved.

Choosing the Right Sublimation Materials

Although the chart above shows the required settings for various substrates, it shouldn’t be assumed sublimation adheres well on all substrates. Sublimation works best on polyester or polyester-coated materials.

To reduce the chances of peeling and cracking, ensure that the fabric contains at least 65% polyester for optimal results.

Reviving Cracked or Peeling Sublimated Items

Since sublimation is typically done on polyester, I will address this accordingly. Re-pressing the fabric with a protective sheet might help minimize the appearance of minor cracks, however, cracks on polyester fabrics may be irreversible if caused by incorrect heat press settings.

Having said that, using matching fabric paint to cover cracks might work as a temporary fix, but it won’t restore the sublimation print to its original quality. Fabric paint can help disguise minor cracks, but it won’t fully repair the damage or replicate the sublimation dye process.