Printing designs is a modern way of creating customized apparel pieces. Print providers are looking for the most cost-effective option on the market for doing this.

Among the many options available, Direct-to-Garment printing, commonly known as DTG printing, has emerged as a cutting-edge and favored choice.

DTG printing stands at the forefront of modern apparel customization technologies, thanks to its remarkable combination of speed and advanced printing capabilities. With DTG printing, the process is as straightforward as using an inkjet printer to apply designs directly onto clothing (much like printing on paper). This innovative approach eliminates the need for traditional screen printing or heat transfers, allowing for intricate and high-quality prints that captivate the eye.

One of the standout advantages of DTG printing is its rapid turnaround time, typically ranging between 3 to 5 business days. This quick production cycle makes it an ideal choice for both small and large-scale apparel customization projects.

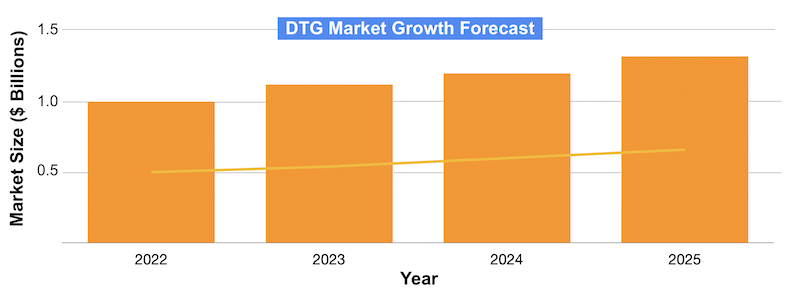

The DTG market is growing so rapidly that it’s estimated it will grow to almost $1.5 billion by 2025. This equates to a Compound Annual Growth Rate of over 12% during the period of 2022-2025.

Key Takeaways

DTG color matching capabilities

Similar to inkjet printers, DTG printers use a CMYK color model. This allows for exact color matching capabilities. As a result, this makes reproducing designs easy and simple.

High quality design printing

DTG printers have the capability of printing detailed high-resolution images. This makes it especially useful for designs containing vibrant colors.

No minimum orders

There are little to no setup costs for DTG printing. Therefore, small or custom design companies need not apply a minimum order quantity for the customer. It’s as simple as pressing start on the printer and making a small profit from that job.

As we delve deeper into the world of DTG printing, we will explore its technology, benefits, and applications, providing you with a comprehensive understanding of this exciting and versatile printing method

What Is Direct-To-Garment Printing?

Direct to garment technology is advanced. It saves you time on your project, as there’s little setup required. You can print any digital design you can conjure from your PC.

DTG printers use specialized water-based inks that are designed to be absorbed by the fabric, resulting in a soft, breathable image.

While it’s a relatively new technology (started in the 90s), it’s now more available worldwide.

Only in the last decade have businesses been switching to it. Marketers and retail brands can communicate their message or identity with little setup costs, which is particularly useful for small businesses. In fact, this could be why the majority of DTG printers (77%) are used by businesses with fewer than 10 employees.

Other DTG Interesting Statistics

- DTG printing accounted for 13.5% of the total garment decoration market in 2018 – survey by Specialty Graphic Imaging Association.

- DTG printing is increasingly popular in the apparel industry, with the global market estimated to reach $1.6 billion by 2026.

- DTG printing is a cost-effective method of garment decoration. The cost per print ranges from $0.50 to $5.00.

Other elements including print quality and resolution are fantastic. It’s arguably better than screen printing and dye sublimation. And unlike other printing methods, it doesn’t create a mess.

There’s a range of color options to chose from. This means being able to personalize your prints to the finest detail without affecting printing cost.

This printing technology allows artists, print providers and services to experiment with their designs.

If undecided whether DTG printing is right for you, consider this. It has way more settings and options that allow you to experiment with prints. Imagine the flexibility a regular inkjet printer has, but instead of printing on paper, you are printing on garments!

How Does DTG Printing Work?

Direct to garment printing is simple. Unlike other printing methods, expertise level isn’t required.

While there are some differences in the process (particularly with larger, more complicated machines), these are some general steps you need to follow for a successful print.

#1 Garment preparation

The initial and crucial step in the garment printing process is proper preparation.

Depending on the fabric’s material and color, pre-treatment becomes essential. This involves the application of a chemical solution onto the fabric. To ensure a smooth print surface and effective penetration of the fixative chemical into the fabric, a squeegee can be employed.

This pre-treatment process serves multiple purposes. It facilitates ink absorption into the fabric’s fibers while safeguarding against fading, thus significantly enhancing the design’s durability and lifespan.

Pre-treatment sprays consist of various chemical emulsions. Generously apply a layer of the spray to the targeted printing area, allowing it to soak for under a minute before commencing the printing process.

Three challenges you’ll face while pre-treating

- Various fabrics need varying amounts of pre-treatment chemicals.

- Inadequate pre-treatment leads to less vibrant colors.

- Excessive pre-treatment can cause ink to flake and crack.

#2 Properly positioning garment in the DTG printer

Achieving flawless prints hinges on meticulous garment placement within the DTG printer.

Once the printing process begins, adjustments to the shirt are not possible, underscoring the importance of precise positioning. Ensure the fabric or textile remains free from creases to avoid any adverse effects on the artwork.

#3 Print the pretreatment

After pretreatment spay has been applied, make sure you remove moisture from the garment using a heat press.

You can now print directly onto the fabric over where the pretreatment was applied!

#4 The printing process

After printing the underbase, you can select your desired colors, patterns, and adjust various settings such as brightness, shading, contrast, and other details.

Once you’ve fine-tuned these settings and found the perfect print options, simply click the ‘print’ button to start the process.

The printing itself is a quick and efficient operation, typically lasting just a couple of minutes. You’ll receive an audible signal, often a beep, indicating the completion of the print job.

Did you know? The average print time for a DTG print on a t-shirt takes roughly two minutes.

DTG printers utilize color cartridges similar to those found in inkjet printers, typically featuring colors like yellow, black, and magenta.

#5 Curing the garment

Following the completion of the printing process, it’s essential to allow your garment to cure properly to prevent premature fading of the print and give it integrity.

For DIY enthusiasts, a conventional heat press can be used for curing. Simply apply heat multiple times until the print securely adheres to the fabric and remains in place.

Alternatively, if you’re operating a professional DTG printing business, a conveyor dryer is the ideal tool for achieving flawless curing of the design or image.

Both methods are effective, so even if you’re not a professional, rest assured that your heat press can still deliver excellent results.

Choosing the Right Materials for Direct-to-Garment Printing

Unlike many other printers and printing methods, DTG printers exclusively use water-based ink. While they can be used with various fabrics, natural ones are the optimal choice.

Natural fabrics possess superior ink absorption capabilities, resulting in prints that are notably vibrant, enhancing the appeal and attractiveness of your designs.

For optimal results with DTG printers, consider using these preferred materials:

- Organic cotton

- Basic cotton

- Ring-spun cotton

- Linen

- Natural textiles

However, it’s advisable to steer clear of polyester and synthetic materials, as they struggle to absorb water-based ink and may pose challenges when used with a DTG printer. While experimenting with these materials is possible, expect potential issues with print quality.

Regardless of the clothing or accessory you aim to decorate, it’s recommended to have a composition containing at least 50% cotton for the best outcomes.

How Long Do DTG Prints Last?

The durability of DTG technology is often raised, which is a crucial concern for potential users. Unlike many other printing methods that yield impressive results but fall short in terms of longevity, direct to garment (DTG) printing offers the perfect blend of quality and durability.

On average, a DTG print can withstand approximately 50 washes, which is comparable to the longevity of items from fast fashion retailers. This longevity is a notable advantage of DTG printing, setting it apart from various digital printing methods that may replicate a design perfectly but lack durability, fading after just a few wash cycles.

Typically, DTG prints can maintain their vibrancy through approximately 50 washes, ensuring the longevity of your custom products and graphics.

For those seeking even greater durability and print longevity, we recommend pretreating the garment and applying an underbase spray. This simple step can extend the lifespan of your clothes far beyond the 50-wash mark, ensuring that your T-shirts remain vibrant and intact for years to come

What Sets Direct to Garment (DTG) Printing Apart from Screen Printing?

While DTG printing offers superior print quality and sustainability, screen printing remains the more popular choice due to its familiarity and efficiency in handling larger quantities.

Screen printing’s advantage lies in its widespread expertise and its ability to cater to high-volume orders with ease. However, DTG printing falls short when it comes to mass production, which, while reducing order minimums, tends to result in higher per-unit costs.

For commercial producers seeking swift turnaround times and large quantities, screen printing remains the optimal investment, as it can accommodate production within a single day, with the only limiting factor being the available labor force.

Conversely, DTG printing boasts superior print quality and vibrant results. Yet, it’s constrained by lower production capabilities, which can be inconvenient when there’s high demand for a particular item.

While screen printing can rapidly generate numerous prints, it often grapples with errors and color discrepancies, necessitating the reprinting of garments. In contrast, DTG printers, although slower and better suited for smaller orders, offer reliability and minimal mistakes, making them the preferred choice for top-quality outputs.

DTG printers are efficient and consistently deliver quality, making them an ideal choice for personal use or small-scale orders. They excel in quick preparation and printing, but each item requires a separate printing process.

If you seek a method for crafting custom clothing with unique prints, DTG machines are a viable option. However, if you plan to incorporate garment printing into your business model and sell these products, screen printing may offer a more cost-effective and efficient solution for larger quantities.