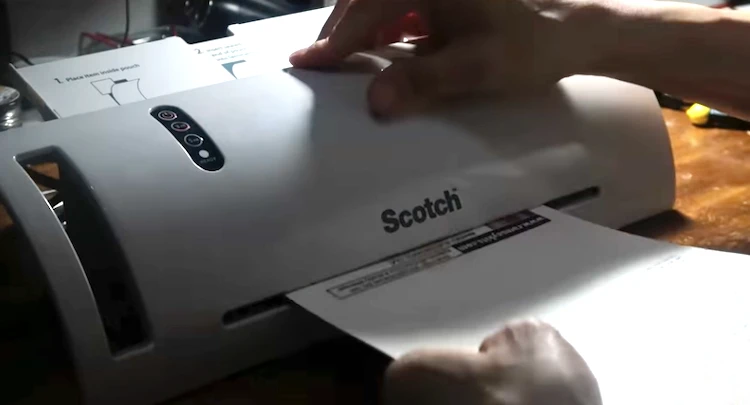

Laminators are staples in offices—and in plenty of home craft rooms too. They protect documents and photos by sealing them inside a laminating pouch with heated rollers.

But when a pouch misfeeds, creases, or gets stuck inside the feed slot, everything grinds to a halt. Professional repairs are often expensive and time-consuming.

The good news: you can usually troubleshoot and unjam a laminator at home, even without a reverse button, by following a few safe steps while the rollers are still warm (always unplug first for safety).

💡 If you’d rather skip the machine altogether, here’s how to laminate without a laminator ↗.

Reasons Why Your Laminator Jams

Laminator jams usually happen for a few common reasons. Identifying the cause is the first step to troubleshooting the machine and preventing the problem from happening again.

Tip 1: Paper or pouch too thick

A paper jam can occur if the combined thickness of your document and laminating pouch exceeds the device’s specifications. Always check the user manual for the correct micron rating and paper weight your thermal laminatorcan handle before starting.

Tip 2: Adhesive on the rollers

Low-quality lamination sheets sometimes leak glue or adhesive residue onto the heated rollers. If not cleaned quickly, this sticky buildup can lead to repeated jams and even roller damage. To avoid this, use high-quality laminating supplies and wipe the rollers with a safe cleaning solution when needed.

Looking for reliable supplies? Protect your projects with high-quality Amazon Exclusive laminating sheets.

👉 Get Laminating Sheets on AmazonHow To Prevent Jams

Prevention is better than cure! The best way to avoid jams is to prepare your documents and laminating pouches properly before feeding them into the machine.

Small mistakes during setup are the most common cause of problems.

💡Tip 1: Align the pouch correctly

Always place the laminating pouch straight and centered in the feed slot. If it enters at an angle, the pouch can wrap around the rollers and cause a jam.

💡Tip 2: Smooth out wrinkles and bubbles

A lamination pouch with air bubbles, creases, or folded edges can jam or come out wrinkled. Make sure your paper is flat and free of folds before inserting it.

💡Tip 3: Use the correct size and thickness

Check your laminator’s specifications for the maximum micron rating or paper thickness. Thicker sheets can get stuck between the heated rollers. For best results, only use pouches designed for your specific model.

💡Tip 4: Choose high-quality pouches

Cheap pouches may leak adhesive onto the rollers, leading to sticky buildup and jams. Investing in high-quality laminating supplies reduces the risk of adhesive residue and improves the finish.

💡Tip 5: Set the right temperature and speed

Follow your user manual for recommended heat settings and lamination speed. For example, 80-micron pouches usually work best at around 130°C and a medium speed. If the pouch moves too slowly at high heat, it can stick to the rollers.

💡Tip 6: Use a pouch carrier (if supported)

Some laminators work better with a pouch carrier sheet, which distributes heat evenly and supports thinner pouches.

How To Fix A Jam

1. With a Release or Reverse Button

Most modern laminators have a reverse button or a release lever. These let you back out a stuck document without taking the machine apart.

- While the machine is still on, press the reverse or release button.

- This detaches the rollers, allowing you to pull the pouch back out.

- Once the jammed sheet is removed, press the button again (or return the lever) to reconnect the rollers.

👉 On some models, the release lever is near the power switch. Check your user guide for exact placement.

2. Without a Release / Reverse Button

If your laminator doesn’t have these features, unjamming can take more effort.

Option A: Simple pull

- Try pulling the pouch firmly from the part that’s still sticking out.

Option B: Partial disassembly

- Turn off and unplug the machine.

- Remove the top cover (on some models this is only a few screws).

- Gently pull the stuck pouch from the rollers.

- Reassemble and test with scrap paper.

Option C: Full disassembly (for older models screwed on all sides)

- Turn off and unplug the laminator.

- Remove screws from all sides and carefully take the machine apart.

- Keep the parts in order (record a video if possible).

- Remove the jammed pouch and reassemble.

⚠️ Safety tip: Wear gloves and work while the rollers are still warm (not hot). Warm rollers soften adhesive, making it easier to pull out the pouch.

3. With Thick Paper or Cardboard

If the jammed sheet isn’t deeply stuck, try pushing it through with a stiffer material:

- Insert a piece of thick paper or cardboard into the feed slot.

- Use it to nudge the jammed pouch forward until it clears.

This won’t work in every case, but it’s worth trying before disassembly.

4. With Tweezers

For pouches stuck near the slot:

- Insert tweezers carefully into the feed slot.

- Grab the edge of the pouch and pull it toward you.

- Once part of it comes free, use your hands to remove the rest.

⚠️ Be careful not to scratch the rollers or plastic housing with the tweezers.

Extra Safety Tips

- Check your warranty: Disassembling may void it.

- Never use knives or blades: They can cut or damage rollers.

- Use proper tools: Choose the right screwdriver for the screws

Cleaning a Laminator After Disassembly

⚠️ Safety First: Always unplug your laminator and let the rollers cool completely before cleaning.

Over time, adhesive residue and debris can build up on the rollers, often leading to repeated jams. Cleaning the rollers after disassembly keeps your machine running smoothly.

Method 1: Xyron Adhesive Eraser

- Open the upper part of the laminator (or fully disassemble if needed).

- Wait until the rollers are cool.

- Rub the eraser across the rollers to lift adhesive.

- Rotate the rollers and repeat until all residue is gone.

- Brush away eraser crumbs before reassembly.

Method 2: Scotch Brite Pad

- Use the same process as above, but apply gentle pressure.

- Be careful not to scratch the roller surface.

Method 3: Toothbrush + Mild Cleanser

- Dip a soft toothbrush in a gentle cleanser, shaking off excess liquid.

- Lightly scrub adhesive spots on the rollers.

- Wipe dry with a clean cloth.

After Cleaning

- Reassemble the laminator.

- Test with a scrap sheet and pouch.

- If jams persist, contact a repair specialist.

Final Thoughts

A jammed laminator doesn’t mean the end of your machine. In most cases, you can clear the rollers safely at home by using the right method—whether that’s a release lever, cardboard push, or careful disassembly.

The real secret is prevention: keep the rollers clean, set the correct heat for your pouches, and always use good-quality laminating sheets. Following these habits will save you from most jams altogether.

Commonly Raised Questions

How can I remove the jammed project if I have an old laminator without a release lever?

You should try removing the pouch by pulling it towards you. For this, a pair of tweezers can be helpful. Or, try to push it with thick paper or cardboard.

If that doesn’t work, you’ll need to disassemble your laminator. Use a screwer and remove parts of your laminator to access the rollers. Ensure that your laminator is turned off and unplugged before doing this.

Why does my laminator jam frequently?

Laminators often get jammed because of the adhesive residue. Remove the debris with an adhesive eraser or a scotch Brite pad. But if you don’t have these products, try to clean the rollers with a clean toothbrush and a mild cleanser. Do not rub the rollers hard. You don’t want to damage them.

How to disassemble the laminator?

For this process, you’ll need to use proper tools. You can remove only the machine’s upper part on the newer models. But, if you have an older model, you’ll have to disassemble the whole laminator.

Ensure that you don’t lose any of the elements and always first check your guarantee.

Most of the warranties note that if you disassemble the laminator, it is no longer under contract.