Most discussions focus on polyester percentage, but there’s a lesser-known variable that affects color saturation, edge sharpness, and ink distribution: material density. Polyester can be tightly woven, loosely knitted, compressed, brushed, or textured, and these structural differences change how sublimation ink vapor moves and bonds.

Density describes how tightly polyester fibers are packed together. A high-density weave offers fewer gaps, while a lower-density structure contains more open space. Because sublimation ink becomes gas, the amount of microscopic space inside the polyester affects where that vapor goes and how concentrated it stays.

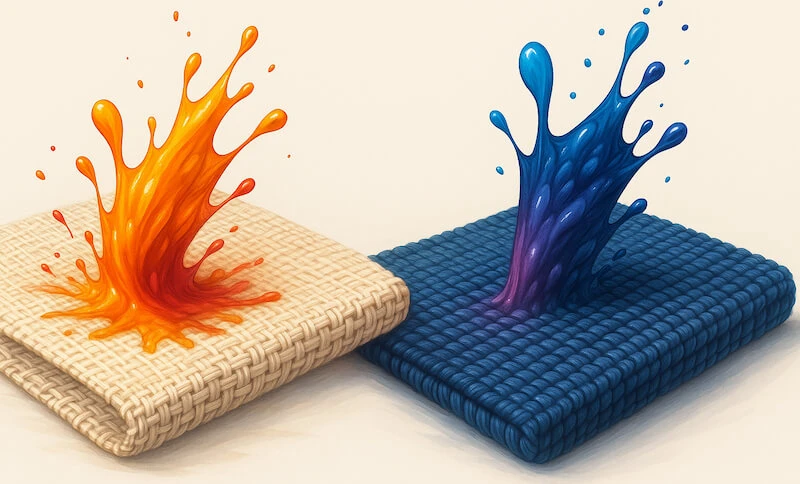

How Material Density Affects Sublimation Ink Absorption in PolyesterHigher-density polyester constrains dye vapor movement, leading to concentrated color and sharper image definition. Lower-density polyester provides more open space within the fiber structure, allowing dye vapor to disperse and reducing saturation and edge precision.

When sublimation ink transitions to gas, it seeks available voids inside the polyester network. In tightly woven or high thread-count polyester, the vapor embeds closer to the surface and remains confined, producing bold and well-defined images. In open-weave or porous polyester (like athletic mesh), the vapor has room to diffuse, which can soften the print or reduce color impact.

| 💡 Although uncommon in apparel fabrics, extremely high-density polyester, such as calendared polyester, polyester films, or heavily compressed microfiber, can become so smooth and sealed that dye vapor has limited space to penetrate, reducing sublimation absorption. |

In this article, we examine how polyester density affects sublimation ink absorption, why weave structure and thread count influence color results, and how understanding density helps determine how to optimize for quality when selecting polyester substrates or evaluating print outcomes.

Key Takeaways

Polyester can have different densities even with identical polymer chemistry.

Density changes through fiber diameter (denier), weave tightness, and finishing processes.

Density affects ink vapor confinement.

Tighter fiber structures hold dye vapor in a more concentrated zone, improving edge sharpness.

Open space controls absorption depth and dispersion.

Looser polyester weaves allow dye vapor to spread, influencing color saturation and detail.

Thread count and weave uniformity contribute to print predictability.

Consistent density creates consistent absorption patterns, reducing variability in appearance.

Optimizing for quality begins with understanding structure.

Material density, not just polyester percentage, influences the final vibrancy and clarity of sublimation prints.

Polyester Can Have Different Densities Even With Identical Polymer Chemistry

Polyester fabrics can share the same polymer composition, chemical makeup, and fiber chemistry while exhibiting significantly different densities. This is because density is governed by physical structure, not molecular structure alone. Even when produced from an identical resin or the same polyester formulation, fabrics can vary widely in how fibers are arranged and packed.

Differences in fiber architecture, fiber layout, and overall physical arrangement determine how tightly polyester filaments occupy space. These elements define the fabric’s material morphology, mechanical structure, and final textile construction, creating measurable structural variation without altering chemistry.

Key non-chemical variables, including filament diameter, yarn twist, weave or knit pattern, and finishing methods, introduce further structural differences. These manufacturing variables control how fibers intersect, compress, or separate, directly affecting density even when the base polymer remains unchanged.

As a result, two polyester substrates with the same chemical identity can behave very differently during sublimation, solely due to differences in physical structure and internal fiber packing.

Density Affects Ink Vapor Confinement

During sublimation, ink transitions into a gas and its vapor behavior is influenced by how much internal space exists within the polyester structure. Material density directly determines vapor containment by controlling how freely gas can move once heat and pressure are applied.

In higher-density substrates, reduced internal volume creates vapor restriction, limiting gas movement and producing a clear confinement effect. This migration limitation leads to constrained diffusion, where dye remains within a defined ink concentration zone instead of spreading outward. The result is stronger ink localization and improved dye retention near the intended print area.

Lower-density materials allow greater vapor flow control loss, increasing limited dispersion only by absence of structural resistance. In these cases, vapor pressure interaction pushes dye into surrounding areas, reducing localized bonding and altering controlled penetration depth.

Overall, density governs how effectively sublimation ink is confined during transfer, directly influencing color strength and image precision through dye confinement rather than chemical interaction.

Open Space Controls Absorption Depth and Dispersion

The amount of open space within a polyester structure determines how far sublimation dye travels once it enters the material. Properties such as porosity, void space, and fiber spacing define the available internal volume that governs dye movement beyond the initial contact zone.

When internal gaps, microvoids, and capillary space are present, the substrate exhibits higher permeability, allowing greater vapor expansion along the available diffusion path. This increases penetration range and alters the overall absorption profile, shifting dye movement deeper into the material rather than remaining near the surface.

Greater open space promotes increased absorption depth through vertical penetration, while also encouraging lateral dispersion as dye migrates into adjacent areas. As dye spread increases, visual density can diminish and fine detail becomes less defined due to broader distribution across the structure.

In contrast, limited open space restricts internal pathways, producing a shallower penetration pattern and more concentrated absorption behavior driven by reduced internal volume rather than surface chemistry.

Thread Count and Weave Uniformity Contribute to Print Predictability

Thread density and weave consistency establish how evenly sublimation ink interacts with a textile across its surface. When fabric uniformity and construction regularity are high, fibers maintain consistent spacing and yarn alignment, creating stable pathways for ink behavior during transfer.

This structural consistency supports uniform ink behavior and consistent absorption, which in turn produce predictable outcomes from print to print. Materials with strong pattern regularity reduce localized anomalies, allowing for repeatable results across multiple runs and production batches.

In contrast, irregular weaving introduces controlled variability challenges. Fluctuations in thread placement or tension disrupt process stability, increasing sensitivity to press conditions and narrowing quality tolerance. Over time, this undermines manufacturing consistency and reduces overall substrate reliability for sublimation workflows.

Reliable print performance depends not on isolated print settings, but on uniform textile construction that supports predictable ink interaction at scale.

Optimizing For Quality Begins With Understanding Structure

Consistent sublimation results require structural awareness rather than reliance on settings alone. Through material evaluation, textile analysis, and fabric assessment, printers can identify how construction characteristics influence material behavior during transfer.

Applying construction knowledge enables accurate substrate selection based on performance needs instead of assumptions. This supports informed decision-making and aligns material choice with intended visual outcomes through design intent alignment.

An engineering perspective emphasizes cause-and-effect reasoning, allowing structural diagnostics to guide adjustments before production. This approach strengthens quality control, supports long-term performance optimization, and improves overall print optimization by matching process conditions to structural characteristics rather than compensating after defects appear.

A technical understanding of structure turns sublimation from trial-and-error into a controlled, repeatable system focused on quality by design.

Related Topics