Screen printing success starts long before ink touches fabric: it starts with mesh selection. Mesh count determines how much ink passes through the screen, how fine your details appear, and whether your print ends up crisp or muddy. But mesh count doesn’t work alone. Thread diameter and mesh tension play equally critical roles, shaping how ink flows, how stencils resolve detail, and how consistently the screen performs. Together, these three factors create the mechanical conditions that define the quality of every print.

How does mesh count affect print quality?Mesh count controls the balance between detail resolution and ink deposit. Higher mesh counts allow fine details by restricting ink flow, while lower mesh counts lay down more ink for bold, opaque prints. Thread diameter and mesh tension modify this behavior by changing the size of the openings, the rigidity of the screen, and the way ink shears through the mesh. These three variables work together to determine clarity, opacity, edge sharpness, and overall print consistency.

Understanding how mesh count, thread diameter, and tension interact gives you predictable control over print outcomes.

In this article, we’ll explain how mesh geometry influences ink flow, why thread diameter changes the shape of the opening, and how proper screen tension reduces dot gain and improves edge definition. With these fundamentals, you’ll be able to choose the right mesh for any ink system, fabric, or level of detail, and avoid the most common print-quality issues.

Key Takeaways

Mesh count defines detail and ink deposit.

Higher mesh counts limit ink flow for crisp, fine details, while lower mesh counts create thicker, more opaque ink layers.

Thread diameter changes how mesh behaves.

Thinner threads create larger, more open mesh geometry even at the same mesh count, increasing ink flow and improving image sharpness.

Mesh tension directly affects print clarity.

Higher tension reduces mesh deflection during printing, minimizing smudging, dot gain, and blurry edges.

Ink performance depends on the full mesh system.

Mesh count, thread diameter, and tension must work together — not in isolation — to produce sharp, consistent, predictable prints.

Mesh Count Defines Detail and Ink Deposit

Mesh count, measured in threads per inch (TPI), controls the size of the mesh openings in a screen, which directly determines ink deposit and detail resolution. As mesh count increases, the stencil opening becomes smaller, restricting ink volume and producing a thin ink layer. This improves fine detail, image resolution, and edge definition, but reduces opacity and overall coverage.

Lower mesh counts create larger mesh opening sizes, allowing more ink laydown per screen pass. The result is a thick ink layer with strong opacity, suited for bold prints, but with reduced line sharpness and a higher risk of dot gain, muddy prints, or washed-out prints in detailed artwork.

Mesh count also affects ink release and ink flow control during the print stroke. Higher mesh counts increase ink shear under squeegee pressure, producing cleaner edges and better halftone reproduction by controlling dot size. Lower mesh counts reduce shear resistance, which can soften edges and reduce image clarity if ink flow is not carefully managed.

In practice, mesh count defines the balance between clarity and coverage: higher counts favor crisp, high-resolution prints, while lower counts prioritize opacity and ink saturation.

Thread Diameter Changes How Mesh behaves

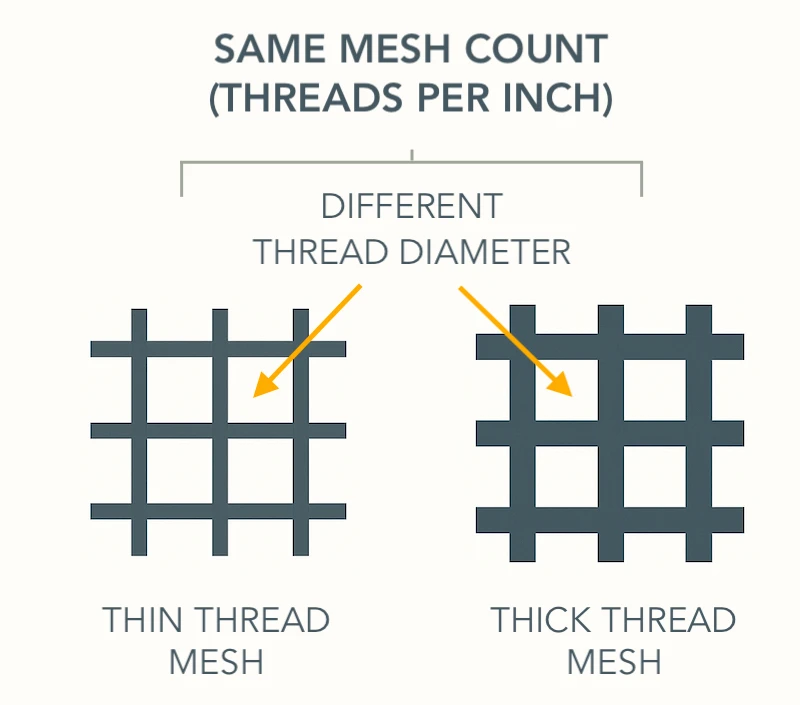

Thread diameter, also called thread thickness, determines the physical mesh geometry of a screen. At the same mesh count, changing the thread cross-section alters mesh openness, open area percentage, and the effective mesh opening. This is why two screens with the same mesh count can produce different results.

A thin thread mesh creates a high-open-area mesh, increasing ink flow rate and improving ink transfer efficiency without increasing mesh count. Thinner threads reduce resistance during the print stroke, allowing ink to pass more cleanly through the stencil. This improves ink release, produces sharper edges, and helps reduce sawtoothing in detailed artwork.

A thick thread mesh forms a low-open-area mesh, restricting ink movement and increasing shear force as ink passes through the screen. While thicker threads can improve mesh stability and durability, they often reduce ink transfer and can soften detail, especially in fine line work.

Modern precision woven mesh, including calendared mesh and high-tension mesh, uses controlled screen fabric construction to optimize openness while maintaining strength. By adjusting thread diameter rather than mesh count alone, printers can achieve smoother prints, more consistent ink deposit, and predictable performance across different ink systems.

Mesh Tension Directly Affects Print Clarity

Mesh tension, often measured as screen tension in newtons (N/cm), controls how much the screen deflects during printing. Proper tension limits screen deflection at the moment of contact, allowing the mesh to separate cleanly from the substrate during snap-off and maintain a consistent off-contact distance.

When tension is too low, the mesh undergoes excessive mesh stretch and screen deformation. This delays mesh rebound, increases mesh relaxation, and leads to tension loss over time. These mechanical failures show up as blurry edges, dot gain, smearing, ghosting, and image distortion, especially on multi-color prints where misregistration becomes more likely.

High, stable tension creates a stable stencil that releases ink evenly and predictably. Faster rebound improves controlled ink release, resulting in even ink transfer, sharper detail, and better print consistency from stroke to stroke. Consistent tension is a key driver of repeatability, particularly on longer production runs.

Maintaining clarity requires proper screen stretching, regular tension measurement, and timely re-tensioning. Frame rigidity plays a critical role in preventing tension drop, directly affecting screen lifespan and long-term print performance.

Ink Performance Depends on the Full Mesh System

Ink behavior is governed by the entire mesh system, not a single setting. Mesh variables and print variables interact within the screen system, and consistent results depend on maintaining proper process control across all of them.

Ink viscosity and ink rheology determine how ink responds to ink shear behavior at the screen surface. These properties influence ink release, ink penetration, and ink leveling, which vary depending on how the screen is configured. A setup that works for one ink type may fail with another if the system is not balanced.

Different inks require different mesh conditions. Plastisol ink, water-based ink, discharge ink, and specialty inks interact differently with the screen and the substrate. Fabric absorbency and garment texture further affect how ink penetrates and levels after contact, influencing final appearance.

True consistency comes from managing interdependent factors such as mesh count vs tension, thread diameter vs ink flow, stencil thickness (EOM), and emulsion build. When these elements are aligned through proper screen setup balance, printers achieve predictable results, consistent prints, repeatable quality, fewer press issues, and optimized print performance.