Screen printing is one of the most popular techniques for creating unique designs and patterns using ink pigment on your garments.

This technique provides various design options. It allows customization of garments and other accessories.

Key Takeaways

Water-based inks

Water-based inks are environmentally friendly and offer a soft, comfortable feel. However, they may not have the same durability as Plastisol inks.

Plastisol inks

Plastisol inks are the popular choice for screen printing, known for their ease of use and application. Being plastic-based, they create a durable and bold print that outlasts water-based inks.

Discharge inks

Discharge inks are ideal for dark fabrics as they remove the dark dye from the material, allowing the design to stand out by printing on top of the bleached area.

Speciality inks

As the name suggests, this ink can add texture and dimension to the print. One such example is puff ink, which contains a foam substance that expands and raises, creating a striking 3D effect.

Always sample test

Before printing any large batch, always test your chosen ink on a sample fabric. This ensures getting the desired results before wasting an entire batch.

If you want to start screen printing but don’t know what ink types would work best, this article is for you.

Exploring Screen Printing Ink Types

Screen printing mostly requires Plastisol and water-based ink. These are the two main types of ink used, although there are others.

They tend to give the best results on a range of garments and complicated design styles.

There are also discharge inks that can help you get a fantastic print. These work on tough and dark garments.

However, there are pros and cons to these types of inks. Which to choose depends on your designs, garments, and preferences.

No matter which you choose. Follow the guidelines and dedicate time and energy to screen printing. Do this, and you will get excellent print results everyone will envy you for.

The Champion: Plastisol Ink in Detail

Plastisol ink is screen printing’s unrivaled champion, celebrated for its widespread use in retail due to its vibrant colors and exceptional durability.

This ink, primarily composed of plastic, starts in liquid form, offering ideal viscosity for creating a wide range of designs. Once cured with heat, it resists fading and peeling, making washing care hassle-free.

Plastisol prints often outlast the fabric itself, demonstrating remarkable longevity. It’s a versatile ink that allows color mixing and the addition of specialty effects like glitter.

While perfect for intricate designs, plastisol is known for its steadfastness on dark garments. However, it’s important to avoid direct ironing, as it’s thermoplastic.

Favored by print shops and large manufacturers, plastisol’s user-friendly nature and adaptability have solidified its place in the industry.

In summary, plastisol ink is a stellar choice for durability and versatility in screen printing, though alternatives are suitable for simpler projects.

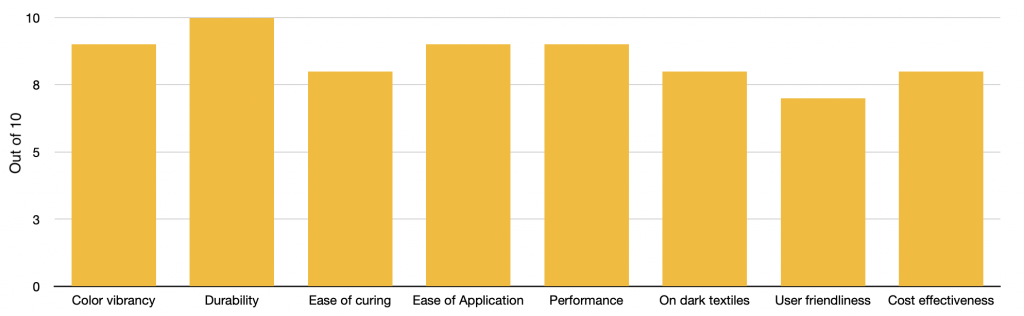

Plastisol ink characteristics include

- Vibrant Colors: Plastisol ink is known for producing vivid and eye-catching colors. It can achieve a wide range of color options, making it suitable for both bold and intricate designs.

- Exceptional Durability: Plastisol ink is incredibly durable and long-lasting. It adheres well to various fabric types and retains its color intensity and shape through numerous wash cycles.

- Easy Curing: Curing Plastisol ink is straightforward. It requires heat to set the ink, making it a reliable choice for both beginners and professionals. This ink can be cured at a relatively low temperature, reducing the risk of damaging delicate fabrics.

- Versatile Application: Plastisol ink is highly versatile. It can be used on a variety of fabric types, including cotton, polyester, and blends. Its flexibility allows for printing on different garments and materials.

- Reliable Performance: This ink type offers consistent and reliable results, making it a preferred choice for commercial and mass production settings.

- Ideal for Dark Garments: Plastisol ink excels in printing on dark-colored garments, where achieving vibrant prints with other inks can be challenging.

- User-Friendly: Its user-friendly nature and ease of application make Plastisol ink a favorite among screen printers. It is forgiving of minor errors and provides a forgiving printing experience.

- Cost-Effective: While it’s true that Plastisol ink may cost more upfront, its durability, ease of use, and versatility make it cost-effective in the long run.

Water-Based Inks: A Closer Look

Water-based inks, gaining popularity in recent years, offer an alternative for screen printing. Comprising water-based ingredients, they’re distinctive as they permeate the fabric to create a print that becomes part of the garment, giving a natural appearance.

While favored for their natural look and soft feel, water-based inks have drawbacks. They lack durability and require careful handling during printing. Factors like humidity can hinder drying, necessitating extended waiting times.

These inks are comfortable to wear and suitable for products designed for comfort, such as sweaters or hoodies. They are also known as acrylic screen printing inks, but they come at a higher cost, making them less cost-effective for frequent screen printing.

Water-based inks are eco-friendly, devoid of harmful chemicals that could trigger allergies or skin irritations, making them a choice for individuals with sensitive skin.

However, it’s important to note that printing in water-based inks is not permanent. Over time, as garments are washed, the prints may wear off, limiting their longevity.

While gaining popularity in the screen printing industry, water-based inks are not without drawbacks, particularly for retailers. They find their niche in DIY projects, where their characteristics are appreciated.

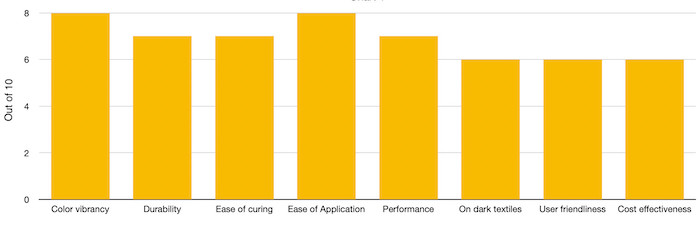

Water-based ink, their eco-friendliness & unique characteristics

- Vibrant Colors: Water-based inks provide vibrant, soft, and natural-looking colors. They become part of the fabric rather than forming a thick layer on top.

- Exceptional Durability: Although not as durable as Plastisol, water-based inks can still withstand multiple washes when properly cared for. They may not crack or fade as quickly as some other ink types.

- Challenging Curing: Curing water-based inks can be more challenging and time-consuming. They require heat and air drying, and the curing process can be affected by humidity levels, making them less forgiving for beginners.

- Soft to the Touch: One of the most appealing features of water-based inks is the soft feel they provide. This makes garments printed with water-based inks comfortable to wear.

- Environmentally Friendly: Water-based inks contain fewer harmful chemicals, making them an eco-friendly choice. They are safer for the environment and for people with sensitive skin.

- Not Permanent: Water-based inks are not permanent. They tend to fade over time, especially with repeated washing. This characteristic makes them better suited for short-run or custom projects.

Discharge Inks: Perfect for Dark Garments

Discharge inks, a subset of water-based inks, feature a unique formulation with an activator that facilitates seamless printing on dark fabrics.

Their key advantage lies in eliminating the need for additional ink layers when printing on dark materials, resulting in soft, natural-feeling prints unburdened by excessive ink.

The activator in discharge ink plays a vital role by removing the original fabric color, replacing it with the desired print hue, without requiring bleaching or multiple layers for visibility.

Discharge inks are the go-to choice when seeking vibrant prints on dark fabrics using water-based inks. However, they come at a higher price point compared to other options, making them a premium alternative.

Despite their color-dissolving action, discharge inks are fabric-friendly and compatible with all screen printing setups. Expect vivid, comfortable prints that boost your clothing confidence.

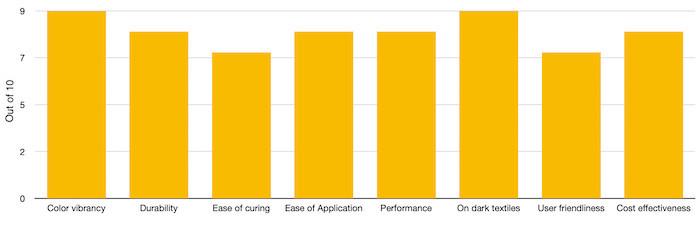

Discharge ink characteristics include

- Vibrant Colors: Discharge inks provide vibrant and bold colors on dark garments without the need for additional layers of ink. The result is a soft, natural-feeling print that doesn’t crack or peel.

- Exceptional Durability: Compared to standard water-based inks, discharge inks offer better durability on dark fabrics. They can withstand repeated washes without significant fading.

- Curing Process: Discharge inks use an activator to remove the fabric’s original color and replace it with the desired print hue. The curing process ensures that the print is colorfast and retains its vibrancy.

- User-Friendly: While discharge inks come at a higher price point, they are user-friendly and compatible with most screen printing setups. They are an ideal choice for those seeking high-quality prints on dark garments.

- Cost-Effective for Specific Needs: Discharge inks are cost-effective when you need to produce high-quality, long-lasting prints on dark fabrics. For specific applications, they provide exceptional value.

Choosing the Right Ink: Key Factors to Consider

Selecting the appropriate ink type for screen printing involves careful consideration of various factors. These include your fabric, desired print, color choices, desired effects, and more. In fact, you may even need to use different inks for each unique design.

Let’s explore the key aspects to pay attention to when seeking the perfect ink type for your printing process.

Material & Textile

Different materials require specific ink considerations. Garments made of polyester and cotton, for example, behave differently when exposed to different types of screen printing ink. Using the wrong ink can result in dye migration, fading, or the print falling apart after just one wash. Take the time to understand the compatibility between the material and the ink type to avoid wasteful purchases.

Each material also requires a specific curing process, with variations in the necessary time and conditions to achieve the desired results. Special fabrics like nylon may have specific requirements, so always research the treatment guidelines before starting the printing process.

Color Characteristics

Not every ink can reproduce the exact color you desire. Plastisol inks and water-based inks produce distinct color characteristics. For example, if you seek gold shimmer or a metallic effect, plastisol ink is the preferred choice, as water-based inks cannot replicate that effect.

Similarly, some pastel and softer shades may be better achieved with acrylic inks rather than vibrant plastisol inks. Thorough research is essential to ensure the chosen ink can achieve your desired color outcome.

Dark garments

Screen printing on dark garments presents unique challenges and requires careful attention. Understanding which inks and colors work best for dark garments, as well as the necessary under base or preparation techniques, is crucial.

Dark garments do not absorb inks well, and not every color will leave a visible mark. Ensure you investigate the appropriate inks and colors that can be successfully transferred to dark fabrics and follow the recommended techniques for a successful printing process.

By considering these factors, you can make informed decisions when selecting screen printing inks, leading to optimal results for your designs and fabric choices.

Navigating the World of Screen Printing Inks

As you can see, screen printing with plastisol, water-based inks, or discharge inks is pretty much the same, but these inks will not work perfectly with all of your garments and designs.

For that reason, always pay attention to these things and check everything twice before you start a screen printing process because you only want the best results.