Picking the right sublimation coating spray can be tricky if you engage in sublimation printing. There are several on the market to select from and to ensure the durability and quality of your prints.

Key Takeaways

Quantity of spray to apply

Do not spray too much solution over the substrate. Doing so will make the fabric stiff and produce scorch marks after pressing. Spray too little and your design will come out dull and not last the test of time!

Importance of drying time

Ensure your spray solution is completely dried after application. Note: you can hover the top platen of your heat press over the fabric. Do not press the fabric, just use it as a heater.

The purpose of using a spray for sublimation

There are several benefits to using sublimation spray on substrates. Click the link on the left to list the advantages

In this article we provide you with all the necessary information on the ins and outs of using a sublimation coating spray. Keep in mind, different sprays may be needed depending on your needs. But they all work in similar ways but with slight differences.

Benefits of Using Sublimation Sprays

Let’s look at the things sublimation sprays can do for the look, feel and details of your printed art work. They can be used to:

- Create glossy or matte printed finishes.

- Protect printed images from scratches, fading and/or smudging.

- Protect the substrate of the print, making it more durable and resistant.

- Add extra durability to the print, making it more resistant to wear and tear over time.

- Enhance the vibrancy and color of the print, making it more vivid and eye-catching.

- Make prints more resistant to the elements and other environmental factors.

What are good sublimation coating spray options?

As mentioned, there is a large selection of sublimation sprays on the market. Some of the most popular are Ngoodiez coating spray and Subli glaze coating spray.

How do these two sprays work?

Ngoodiez coating for sublimation ink

This is one of the most popular spray options. The Ngoodiez coating spray ensures the applied sublimation ink stays in place. It lasts far longer than if you were to put it in the wash without the spray. The spray comes premixed in the bottle ready for application.

Dying time is minimal, meaning you are able to complete the printing process sooner. The high gloss finish of this coat guarantees a finished product that looks professional and vibrant!

This spray works well on a number of cotton blended fabric items. This includes socks, towels, tote bags, pillows and more. Thanks to this process, small business owners can sell a plethora of products, giving customers an array of products to purchase.

This spray can be purchased online, including the Amazon store and other shops.

Watch this video: Sublimation on 100% cotton using spray solution!

Subli glaze coating for sublimations

Subli spray is used on a number of hard material surfaces, like wood, glass and stone. This spray is safe to use on food utensils, meaning that you can sublimate on glasses and ceramic cups. However, it is not suitable for cotton blended fabrics. So, if you are looking for a cotton sublimation spray, Ngoodiez is the one for you! That is the main comparison between the two.

Shake the bottle well. Make sure that the surface of the item you intend to spray is moisture and germ free. This ensures the spray has a chance of providing protection and durability to your design.

While applying coatings over the desired area, ensure some distance between the spray bottle and the dye sublimation ink. Let the concentrate air dry for at least 10 minutes. After this, put it in the oven at 320°F (160°C).

Here is a short explanation of how to use sublimation spray for cotton:

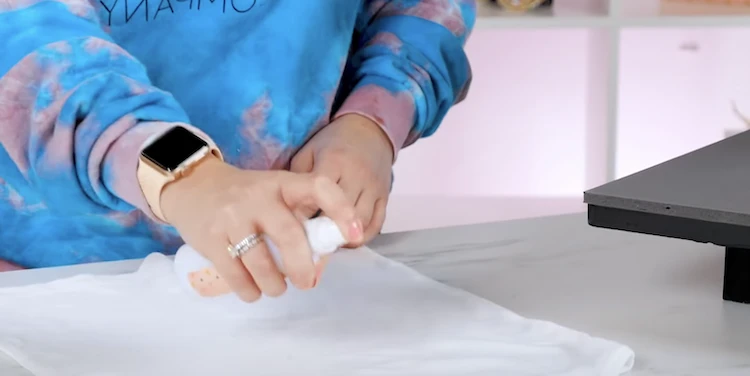

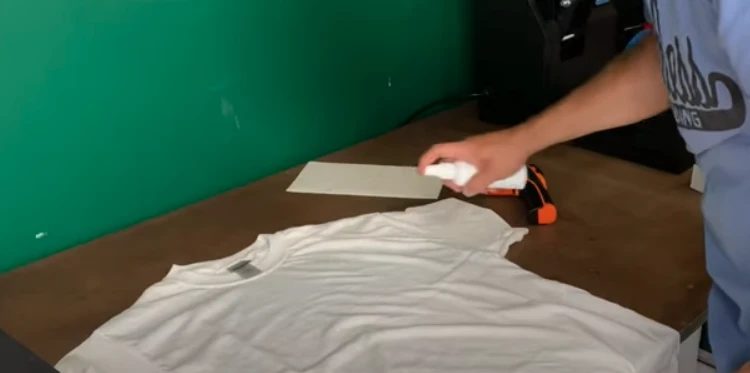

- Before spraying, insert a cardboard (or plastic) board inside your cotton blended fabric. This prevents spray transfer.

- Apply a generous amount of spray onto your cotton blend fabric.

- Let the spray dry for a few minutes.

- Continue with the process of sublimating.

What Other Substrates Can Sublimation Spray Be Used On?

Although sublimation spray is not effective on 100% cotton fabric, it is possible to use the solution on cotton / polyester blends.

Other substrates sublimation spray solution can be used on:

- Ceramic tile

- Mug

- Metal sheet

- Plastic

- Hat

- Mousepad

- Keychain

Do Colors Stay Vibrant After Washing?

Choosing accessories meant for sublimating on cotton or cotton blended fabrics may be of concern. Depending on the spray, the final image may fade after a few washes.

One of the tips to prevent this and help the spray formula do its job is to use cold water to wash your clothing items. Let them air dry instead of putting them in the dryer.

Ultimately though, to give yourself the best chance, is to get your sublimation print to come out bright during the printing process. Failing to achieve this crucial step means no amount of spray will protect color vibrancy.

What is needed for sublimation besides a sublimation spray?

If you are planning on taking on the sublimation operation, it is important to know what other materials and machines you might need for this process. If you have a small business that specializes in sublimation decoration, you will probably want to have your own equipment to do so.

Here is a short list of items needed for sublimation:

- A sublimation printer

- Sublimation paper

- Heat resistant tape

- Lint roll

- Heat press

Why are items needed?

The process of sublimation is no particularly difficult. But it is a process that demands a bit of preparation and investment. These items will allow for professional-looking products that will last longer and ensure customer satisfaction.

The printer is an essential part of sublimation. It is used to print the desired design onto your items by using special inks, temperature, and pressure. This way the image that is transferred is sure to bond to the fabric for a long time.

Sublimation paper (or transfer paper) is a special type of paper. You must have this paper in order to print out your designs. It also provides a plethora of creative options. For these reasons virtually any design type can be printed on t-shirt, clothing or other substrates by using this paper.

Heat-resistant tape is also a handy thing to have. It will ensure that your design does not move. When positioning the paper into your printer, you should apply this tape in order to make sure you achieve the desired results. It is designed to withstand high temperatures and peels off easily after printing.

It is recommended to lint roll your items of clothing before sublimating. This helps remove any dirt and specs of fabric that will interfere with the printing process.

A heat press is used for sublimating on a number of materials. The purpose of this machine is to ensure the right temperature and pressure is applied during the transfer process. It is therefore a necessary tool for this process.

Conclusion

All in all, using sublimation coatings to coat different items is a fairly simple process. The instructions are usually provided in the packaging of the spray.

This type of spray is manufactured to make your designs last for longer and also more resistant to damage. In some cases, they can improve the look of your artwork by giving it a gloss (making it stand out more).

Applying even coats is also important. It is not advised you drench your items in the coating. Always be sure to read the instructions. Some products come ready for use, while others come in concentrated levels that need to be diluted.

FAQ

What is a sublimation spray?

This spray is designed to be applied on various surfaces to protect them and/or enhance the visual appearance of the sublimation print.

What surfaces can I use sublimation spray on?

Such sprays are designed for a variety of surfaces. These include wood, plastic, metal, ceramic and fabric. There’s not one spray for all substrates. Sometimes you have to get specific sprays for specific materials – always read the instructions.

Does the color of the fabric impact the end results?

Usually yes, it is recommended that you sublimate on light fabrics and avoid doing so on darker ones. Some formulas may be suitable for slightly darker materials, but the general rule is that light fabric color is the best option when it comes to sublimating on items of clothing.