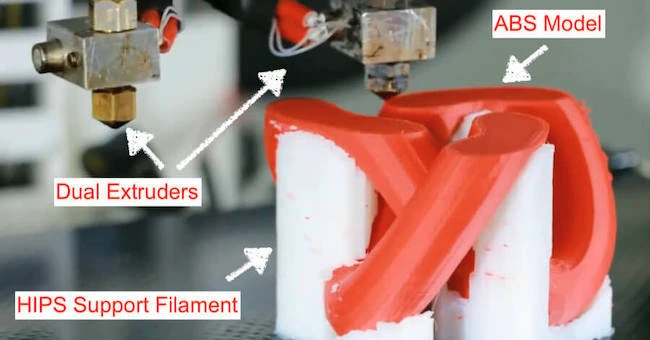

High Impact Polystyrene is a filament that’s frequently used as a support material. The reason it acts well as a support material is because it’s easily broken down by applying Limonene.

As a result, the filament can be dissolved, allowing for a clean high-quality print, as no scraping, pulling, cutting or other forms of “aggressive” removal is required. Essentially, there is less chance of damaging your final print during the clean-up process.

This does not limit HIPS performance as a conventional filament for printing models. It has similar properties to ABS; it’s easy to print with, has less chance of warping, it’s dimensionally more stable and slightly lighter, making it ideal for parts that end up getting worn out and/or require a weight advantage.

Furthermore, HIPS and ABS have similar strengths & stiffnesses and print at around the same temperature (approx. 230°C). As a result, these two filament types compliment each other well, particularly when using dual extruders during the same printing process.

HIPS & PLA Compatibility

We’ve talked about how HIPS and ABS compliment each other due to their similar properties. However, where does PLA stand in this partnership?

The main problem here is printing temperature. PLA has a significantly lower printing temperature than HIPS, making the two materials incompatible during the same print process.

As a result polyvinyl alcohol (PVA) would be a better alternative as a support material as it and PLA have similar printing temperatures.

“PVA can be dissolved in water – an environmentally friendly option”

Pros & Cons of Using HIPS

Before making your purchase, there are a few things to consider regarding HIPS. [highlight-it color-1]Here’s a quick guide as to what makes using HIPS both a good and bad material[/highlight-it].

What Makes HIPS A Good Filament To Use

- Strong & Durable

- Low Cost

- Cheap

- Decent Impactive Resistance

- Water Resistance (Non-hydroscopic)

- Great Supportive Material (non aggressive removal capabilities)

- Light Weight

- Easily Paintable

- Recyclable & Non Toxic

What Makes HIPS A Bad Filament To Use

- Requires Heating Bed (Prevent warping)

- Requires High Printing Temperatures

- Ventilation Recommended (Release of Styrene in the air)

Hardware Requirements

Although there are some similarities between HIPS and ABS, it’s still recommended to check your printer to ensure the best print quality.

As a results, I have created an easy to follow hardware printer requirement listed below.

Flat Bed Requirement For HIPS

A heat bed is required to prevent any warping during the print process (particularly for the first layer)

Bed Temp Range → 90-115 °C

HIPS Extruder Temperature

No special hot-end is required when using HIPS filaments, however, the required temperature range is as below:

Temp Range → 220-240 °C

Cooling Equipment Requirements

HIPS is still susceptible to warping. Therefore further cooling is not a requirement.

Cooling Fan → Not Required

Build Surface Type

Good adhesion and a heated bed are both required to prevent warping. Here are adhesion recommendations.

Adhesion Type → Glue Stick, Glass Plate, Kapton Tape

Ventilation, Fumes & Safety Requirements

Although HIPS is food safe, non-toxic, fully recyclable and non-hydroscopic, it does have a downside inasmuch as, just like ABS, it releases small amount of fumes.

Release of styrene in the air can be inhaled as you breathe, and enter the body through your lungs. In large doses it may impact the nervous system and include the following symptoms; color vision changes, slow reaction time (like drunkenness), tiredness and problems with balance.

It is however important not to panic, as when printing, only small amounts of styrene is released in the air. Having said that, in time, with every print session, this amount accumulates.

Here’s an interesting public health statement on Styrene [R] by ATSDR

HIPS Filament Applications

This plastic is frequently used on prototyping due to its dimensional stability, particularly when exposed to high temperatures. With this, HIPS plastic is also resistant to cracking making it a good material for home appliances, toys and packaging.

With this in mind, it’s also easy to paint and glue.

Getting Started With HIPS Filaments

You now know a little more about HIPS filaments and its uses in 3D printing.

I have therefore added some recommendations of which manufacturers you can use, and why it’s a filament type you might want to try out.

FAQ

What are some of the properties HIPS filaments have?

HIPS has various properties that make it a great plastic to use. Here are 7 properties:

1. Resistant to moisture

2. Strong & hard-wearing

3. Resistant to impact

4. Dissolvable in Limonene (support material)

5. Non toxic (food safe)

6. Recyclable

7. Light

At what temperatures do I print with HIPS filament?

There will be temperature variations depending on your printer and the type of HIPS filament you are using. However, the recommended extruder temperature range for HIPS is 220-240°C and 90-115°C for the bed temperature.

What does hips filament dissolve in?

Limonene! This is essentially the oil extracted from the peels of citrus fruits such as oranges. It’s the most common terpenes found in nature, making it environmentally friendly use for dissolving HIPS plastic.

Closing Thoughts

HIPS is often under-rated as being just an other “support material”. The material that’s simply used to get the desired results for an other material, only to be discarded when no longer in need.

With mechanical properties that are in par with PLA and even ABS, this plastic should be given more credit than it’s getting. Add the fact it’s also food-safe, and you undoubtedly have a winner!

Give it a try and see how you get on with it, you might be pleasantly surprised.