With 3D printers getting better, while also becoming more affordable, it’s getting increasingly confusing and harder to choose the right one for your needs. Add more brands entering the market and the confusion only grows.

Therefore, in this post, we take a look at and explain the differences between the current competing and most popular 3D printing technologies out there; FDM and SLA and see which you should pick if stuck for choice.

Before getting started though, here’s a brief explanation between the two and their differences.

Differences Between FDM and SLA Explained

- FDM applies layers of plastic to build up the model

- SLA applies cured resin to create a model

- FDM requires cooling to set the plastic

- SLA requires a laser to cure the resin

- Generally, SLA technology produces smoother & better quality prints

- FDM printers generally can print faster, but at compromised quality

- FDM have the filament as the only consumable

- SLA has resin, a vat & build platform as consumables

- FDM has more variety of materials and colors for creating 3D models

- SLA has fewer 3rd party suppliers which drives up cost of materials

For a more comprehensive explanation, let’s look at the main characteristics between FDM & SLA technologies as shown below?

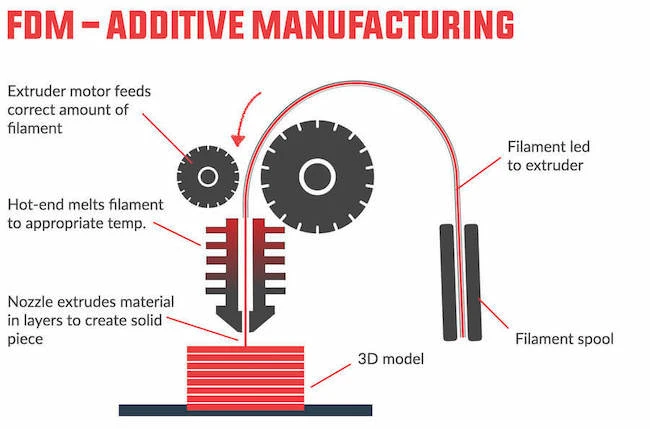

What Is FDM 3D Printing & How Does It Work?

FDM (Fused Deposition Modeling) is a type of “additive manufacturing”, meaning that the 3D model is not created in one whole process such as moulding. Rather it’s created by means of adding continuous layers of melted material (typically a type of plastic) to build up the final solid 3D model from the bottom up.

The model then cools down to one solid piece.

FDM printers are made up of components that move in all three axes, the x-axis, y-axis and z-axis to create the 3D object (logical, right?). However, there are more components that make up a FDM printer, such as parts that are directly involved in printing, moving part, a frame for stability and the like.

The printer must read a 3D generated model (usually in .STL format) created using a 3D package and then start to print it out. Usually this is saved on a USB stick and can be plugged into the printer for it to read.

Because FDM 3D printers are designed to created things by means of layering, it means that the 3D generated model (which is essentially solid) must then be sliced up into layers using a Slicer Software.

Watch this video: An Understanding of FDM Printing (02 mins 22 secs)

To save time, skip to timeline 00:22!

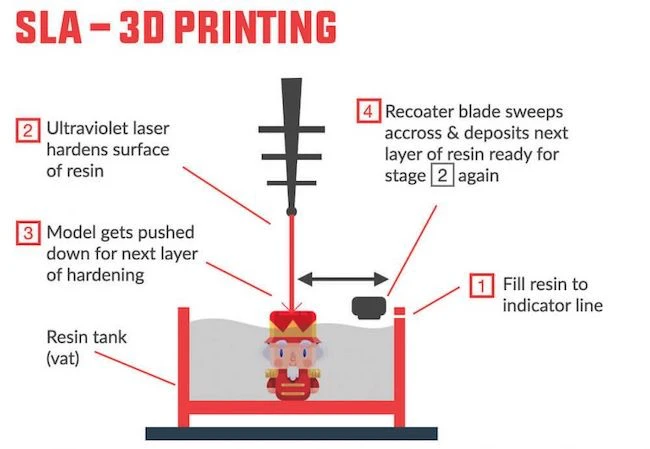

What Is SLA 3D Printing & How Does It Work?

SLA (Stereolithography) works very differently to FDM inasmuch as it does not build up layers of heated plastic materials to create the finished product after cooling.

However, it is still an “additive manufacturing” process where UV light is used to cure liquefied layers of resin to create the finished product.

The process of reading and slicing up the model using slicer software is the same though!

A vat is filled with a photo-curable resin and an ultraviolet laser beam shines onto the layer of resin.

The laser beam traces a pattern on the surface of the liquid resin which ultimately solidifies the pattern. The process continues, and each layer that hardens solidifies to the next layer which eventually creates the final product.

Essentially, this process works in reverse order to FDM, inasmuch as it builds the 3D model from the top down. Having said that, some printers do allow for printing from the “bottom up” which has a huge advantage, such as the printed model being larger than the vat itself.

Watch this video: An Understanding of SLA Printing (02 mins 46 secs)

To save time, skip to timeline 00:22!

3D Printer Recommendations

It’s hard to provide a definative answer as to which printer technogloy you should go for. There are many determining factors that can create overwhelm and over choice.

ANYCUBIC Photon [Resin Printer]

In short, if high precision and smooth finish is your priority with cost being of lesser importance, then use a SLA or DLP printer.

For this our recommendation is the ANYCUBIC Photon Printer which is a DLP printer. Although not a SLA printer, the technologies are similar inasmuch as they use resin which requires a laser to cure.

SLA have a reputation for being able to sustain higher quality finishes, but this is slowly changing and with DLP hardening an entire layer in one go, this means faster print times.

What we like

What needs improving

Creality Ender 3 Pro [FDM Printer]

If cost does play a role, use an FDM printer.

For this, our recommendation is the Creality Ender 3 Pro because of its print quality, affordability, ease of assembly, decent print volume and hackable & upgradable.

The Ender 3 Pro also offers features you don’t find in more expensive 3D printers, such as decent build volume [220 x 220 x 250mm], magnetic print bed, power recovery mode, and a tight filament pathway that makes use of flexible materials easier.

What we like

What needs improving

What Are The Print Quality Differences?

The above title in itself suggests there is competition between FDM and SLA printing techniques, and that statement is becoming even truer as SLA are hitting the market even harder than ever before due to their increased affordability.

However, what makes SLA printers even more attractive is their ability to produce prints/models that are ultimately more detailed and smoother in finish compared to their plastic layer building friends. This is due to being able to print at smaller layer heights (Z-axis) and more importantly a higher XY-resolution.

FDM Print Quality Factors To Consider

- Nozzle size affects resolution / print quality

- The weight of layers may squeeze lower layers and deform print

- Warping caused when plastics such as PLA & ABS cool after heating

- Missing layers are common when the printer fails to provide the correct amount of plastic

- Stringing happens when some material drops from the nozzle onto unwanted parts of the print

- Nozzle blockage is common

- More mechanical and software tinkering/calibration for optimal printing

SLA Print Quality Factors To Consider

- Consistently creates higher resolution prints with fewer flaws

- More accurate prints (closer in dimensions, shape and size to the actual CAD file)

- Less force applied to model during the print (improved surface finish)

- As resin is photo-curable by UV light, long terms exposure to sunlight can reduce models mechanical strength.

- The resin is sticky and completed prints need to be cleaned out with alcohol to remove stickiness

- Printing from the “top-down” means the model’s height cannot be greater than the depth of resin in the vat.

- Tied to purchasing resin from the manufacturer (currently to few third-party suppliers)

- Post-finishing required – removal of support structures after print

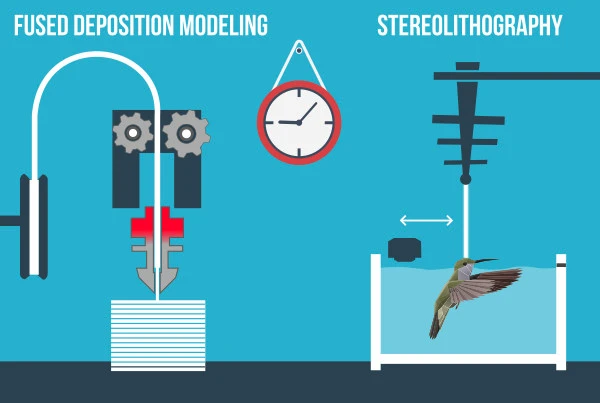

How Do Print Times Vary Between FDM & SLA?

Desktop 3D printer technology is getting faster, but some may argue it is not quite at the stage where most would like. So naturally, you would want to know which prints out faster before forking out the bill on your brand new hardware.

Deep down, I think we all know there is going to have to be some form of compromise between quality against speed of print and it is up to you to decide which way to go depending on your printing requirements.

Yet another “well it depends” answer? That was not very helpful!

You are absolutely correct, so what we decided to do is contact various experts on using 3D printers and ask them what they thought.

Asking The Experts About Printing Technology Speeds

We ask two experts in the 3D printing industry three related questions

Question 1: Generally speaking, which technology can be set to print the fastest, FDM or SLA?

Question 2: Can you describe why this technology is able to printer quicker than the other?

Question 3: Which printing technology would you generally pick and why?

FDM vs SLA Printing Times

- FDM Standard Setting: 0.3-1.7 in/hr

- SLA Built-In Rate: 0.3 – 0.7 in/hr

FDM vs SLA: Running Cost Comparisons

It is important to note that here we are not talking about maintenance cost of each technology (something I will need to look into in the future) or the power consumption comparison, but rather the cost of materials and other directly related factors.

FDM 3D Printing Cost

Fused Deposition Modeling has the advantage of having only one consumable, which are the filament rolls. They are by in large the same standardized rolls that can be used on all FDM printers. As a result, many third-party providers selling the product which increases competition and therefore reduces cost, particularly during recent years.

A simple filament can cost as little as $25 for one kilo (1Kg) of roll, however, some specialized rolls can cost more!

There are two “standard” diameters of filament that can be used for FDM printers, these are 1.75mm & 3mm diameters.

Pro Tip: It’s important to try and find a supplier that provides a uniform diameter of filament throughout its entire length. This allows for better quality prints and reduces the chances of blockages and machine maintenance.

If this is not feasible for the time being, you can then try extrusion calibration to compensate for the varying diameters throughout a filament’s length.

SLA 3D Printing Resin Cost

StereoLithoGraphy, unfortunately, has a few more consumables than Fused Deposition Modeling. SLA technology uses resin to print out a model and this is considerably more expensive than filaments. One liter (1L) of standard resin can cost anywhere between $150-$250 depending on which printer you have.

This price should start to drop when third-party suppliers start offering their compatible versions for each printer, but having said that, it will most likely still remain more expensive than filaments.

The tank or vat also has to be replaced after about 3-4 liters of resin has been printed. In time the build-up of resin smudges the tank’s transparent walls and interferes with the UV light passing through and can no longer precisely project the image which in turn effects print quality. A resin tank can cost about $60 to buy new.

The other consumable is the build platform (the area the printed models rests on during printing). This does not need to be replaced so often, but in time when the model is removed, the surface gets spoiled and somewhat ruined. One platform can cost up to $100.

Other SLA Consumables To Consider

| Image | Product | Feature | Price |

|---|---|---|---|

|

Protection

|

MedPride Nitrile Exam Gloves (powder free)

|

Resin can be an irritant and react differently on each person... better be safe than sorry! | Check Amazon |

|

Respirator

|

Half Facepiece Reusable Respirator

|

UV-cured resins contains the toxin MMA. Reduce exposure by wearing a mask. | Check Amazon |

|

Removal tool

|

Putty Knife Scraper Tool

|

Use a scrapper tool to remove prints or failed prints from the build plate. | Check Amazon |

|

Removal tool 2

|

Plastic Razor Blade Scraper

|

For failed prints that stick to the FEP film. Plastic reduces the chances for scratching. | Check Amazon |

|

Cleaning

|

Isopropyl Alcohol 99% (IPA)

|

To rinse finished prints and clean tools that have come in contact with resin. | Check Amazon |

Resin 3D Printer (SLA) vs Filament (FDM): When To Use Which?

If we look at asking the experts ⬆ section above and read Answer 3 provided, you will get an idea of which technology suits which conditions and/or requirements.

Comparing FDM & SLA Materials, Colours & Availability

Like any machine, there are running costs, and for 3D printers, the main one is consumables (essentially the materials needed to create the 3D print). One of the advantages that FDM has over SLA is the variety of materials and colors that are on offer, generally lower cost of the materials, and just as importantly the variety of third-party consumerables (ability to shop around).

3D Printer Filament Material Types (FDM): Overview

Having said that one advantage SLA has over FDM is the accuracy of prints that can be used for anatomical regions of patients and for accurate prototyping for businesses to access design and functionality of their product or for advertising the final product.

One of the major disadvantages of SLA, however, is the limited choice of resins which cannot be exchanged between printers… essentially (at least for the time being) each manufacturer will design their resin vat to fit only their printer(s)

With SLA, the resin is quite expensive compared to equal quantities you get with filaments, not to mention a limitation of materials & colors too and you are (at least for the time being) tied to purchasing the resin from the same company you bought the printer from.

However, there are different types of resin available for purchase to allow your final prints to have different physical properties.

Removal Comparison Between SLA & FDM After Printing

We often forget that once your print is complete, there is still a bit of work to be done and that is removing your print from the print bed.

In general, removing FDM prints is relatively easy and may require a little assistance with a knife to release those stubbornly stuck ones… but all in all, it is relatively easy to do.

SLA, however, does pose some potential difficulties in comparison. Resin will reside on the platform in large quantities which first has to be removed before being able to get to your print. This requires the use of a knife, palette knife or spatula and takes a lot more effort.

After that there’s yet more post processing such as applying pure alcohol on your final print to remove any excess resin, during which you must always wear gloves and face mask due to the toxiicity of resin in liquid form.

Note: Like all technology things are constantly improving. Companies such as Carbon3D and WASP have come up with some new ideas to prevent this accumulation of resin:

- Carbon3D use oxygen to keep the resin at the surface and preventing it from hardening. This eliminates the build-up around your model.

- WASP claim by moving their projector to the top of the bath has solved this problem.

FAQ

When was stereolithography printing invented?

Charles W. Hull (AKA Chuck Hull) is credited for inventing StereoLithoGraphy and is considered to be the father of 3D printing which has shaped the technology to what it is today. Hull knew it would probably take about 30 years before the technology reached the homes of everyday people.

The concept of SLA printing emerged to Hull when working for a small business that made tough coatings for tables using ultraviolet lights. He quickly realized that this same process could be used to create three-dimensional parts.

He created his printer back in 1983, but it was not until 8th of August 1984 that he coined the term stereolithography in his patent apparatus for the production of three-dimensional objects by stereolithography.

How accurate is stereolithography printing?

SLA is quite possibly the preferred 3D printing technology for accurate prototyping for designers of any niche where tolerances of parts are paramount.

Being able to create accurately formed prototypes (particularly dynamic / moving parts) enables verification that the design will or will not work before committing to any production route.

Not only is stereolithography one of the most accurate printing methods, it also provides good durability, along with a clean surface finish.

One other factor to note, the size of the print can affect accuracy. For example, conventional FDM printing starts to struggle when printing smaller / tiny objects. However, the resolution of SLA is determined by the spot size of the UV laser and therefore can handle smaller prints with more accuracy.

How does stereolithography 3D layering work?

SLA works very differently to FDM inasmuch as it does not build up layers of heated plastic materials to create the finished product. However, it is still an “additive manufacturing” process where UV light is used to harden/cure liquefied resin to create the finished product.

The process of reading and slicing up the model using slicer software is the same though!

A vat is filled with a photo-curable resin and an ultraviolet laser beam shines onto the layer of resin. The laser beam traces a pattern on the surface of the liquid resin which ultimately solidifies the pattern. The process continues, and each layer that hardens, solidifies to the next layer in order to create the final product. Essentially, this process works in reverse order to FDM, inasmuch as it builds the 3D model from the top down. Although some printers do allow for printing from the “bottom up” which has a huge advantage, the printed model can be much bigger than the vat itself.

SLA vs FDM material strength, which should you choose?

It’s not so much to do with the type of material that produces the best strength, but rather the process by which the material is cured.

In general FDM produces a harder plastic with a better tensile strength and heat resistance. The reason is the laser used in relatively inexpensive SLA printers do not have the capacity or wavelength to cure the resin at similar strength. For this to happen you would require a far more powerful laser that would push the price of your SLA printer up to the $10,000+ range (a bit too pricey for the average hobbyist).

Final Thoughts

Unfortunately, I cannot make the decision for you as to whether you should go FDM or SLA. As stated on the article, there are many factors to consider, such as print time, print quality and which technology require the most consumables (price)!

However, if you are new to the 3D printing world, then going with FDM is likely a safer bet as the initial cost will likely be lower. If you discover the 3D printing isn’t for you, then you haven’t lost much. Conversely, if you find you love it, you can eventually “upgrade” to SLA or other more advantages 3D printing technologies.